WHO we are

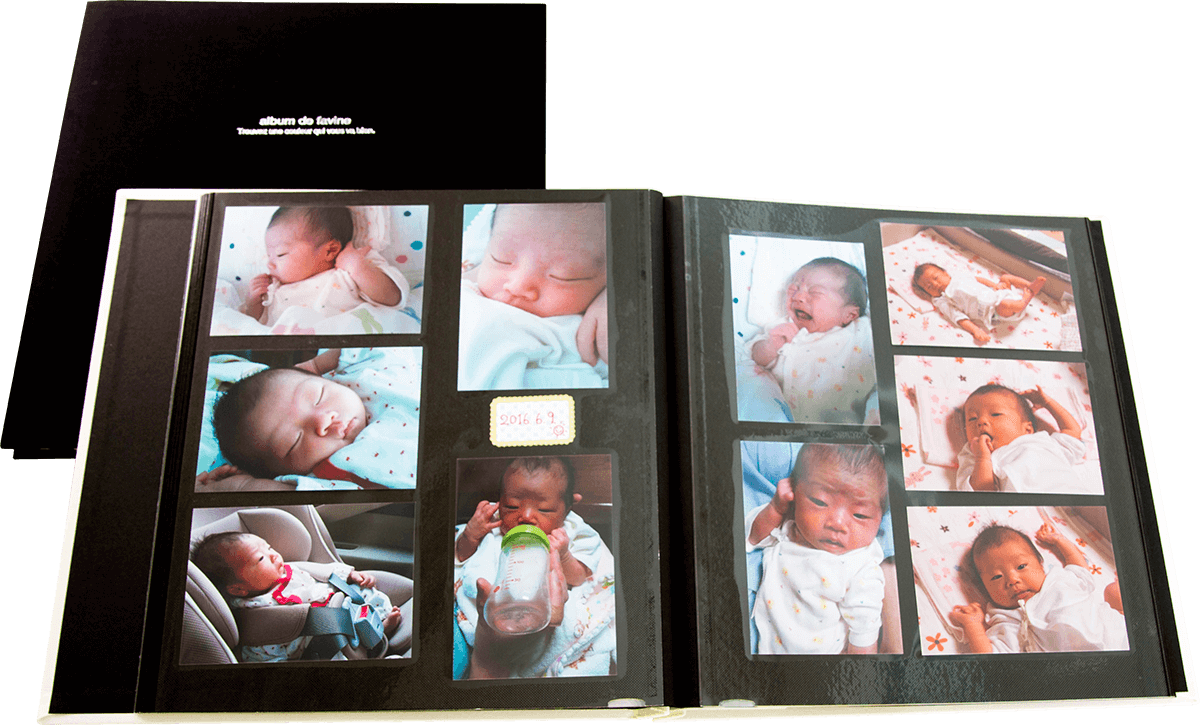

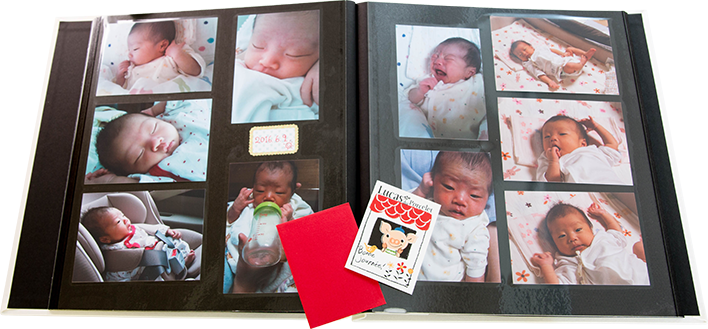

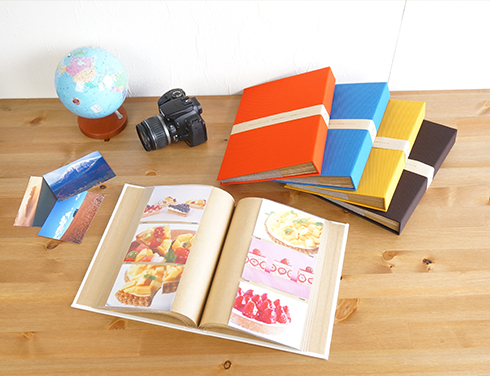

Photo album’s maker developing a global business in over 30 countries for 50 years.

Who the best maker of photo album is?

Our global business for photo album started in 1968 has been expanding to over 30 countries. It includes OEM business in USA and European markets with high evaluation such as “the highest quality” and “punctual delivery” from most buyers in those countries. One of unique characteristics in our business is that our photo albums have been distributed in many Middle East countries including Saudi Arabia, Dubai, Kuwait, Oman etc for over 30 years. Nakabayashi has been, as representative photo album’s maker of Japan, fostering the highest technologies and quality to protect your precious pictures and developing a lot of original products. We proud ourselves on our “made in Japan products”, overwhelmingly higher quality than other manufacturer’s products.

- Total sales for all sorts of photo albums

- About million pieces

- Number of our products

- About sku

- Only one manufacture of photo album in JAPAN

Main export countries

| USA | 20% |

|---|---|

| Europe | 25% |

| China | 20% |

| Asia | 25% |

| Oceania | 10% |

Why Nakabayashi’s magnetic sheet photo albums are so different?

No curl

No discoloration

No bubble under protection film

Our special magnetic sheet bourn under strictly quality control protects the sheet and picture from deterioration.

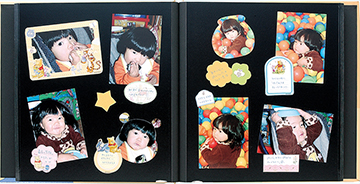

Our post-bound photo albums are longtime seller products sold globally since 1968. In addition to the unique characteristic of being able to increase number of sheets with extension screws, the overwhelming high quality under the elaborate quality check is another reason for great popularity.

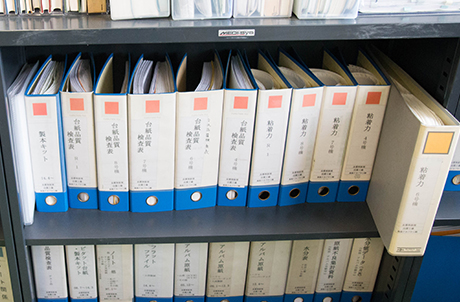

1. Thorough quality control of the magnetic sheet

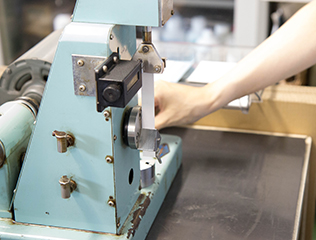

Paper’s quality test

The magnetic sheet is, basically, prone to curl, wrinkle or bubble by temperature and moisture. We always source the most appropriate paper to our magnetic sheet from the paper manufacturer with our rich store of data about any of papers.

The paper’s test introduced here is done for the purpose of judging about whether the paper we sourced will adapt to our criteria of quality or not. Though the paper manufacturer will do the same test by themselves, we adopt the double-check system to see the test results of both the paper manufacturer and us.

Investigation item

- ① Grammage

(weight per m3) - ② Thickness

- ③ Density

(weight per cm2) - ④ Moisture value

(moisture percentage) - ⑤ Tear strength

- ⑥ Tension strength

- ⑦ Smoothness

(smoothness of surface) - ⑧ Surface strength

- ⑨ Interlaminar strength

- ⑩ Degree of sizing

- ⑪ Water absorbency

- ⑫ Folding endurance

- ⑬ Stiffness

- ⑭ Moistness elongation

Test instrument

- ① Electric scales

- ② Tensile tester

- ③ Tearing tester

- ④ Folding endurance tester

- ⑤ Wear resistance tester

- ⑥ Stiffness tester

- ⑦ Smoothness tester

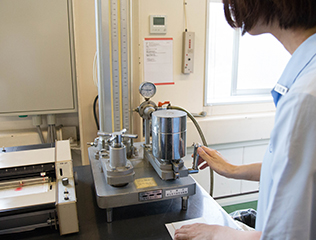

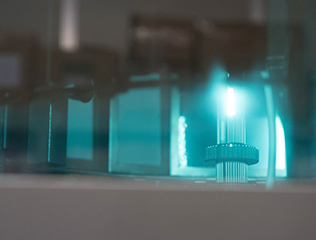

Magnetic Sheet Quality Test

We especially pay attention to moisture value in the magnetic sheet (content ratio of moisture) and adherence power (the power to peel PP protective film out of the sheet) at the point of production. Paper has the nature to be naturally back to the moisture level of the paper-making. Then, adjusting it to an appropriate moisture level is required at the point of production. In addition, the adhesive power of our adhesive compound is, due to water-based adhesive, prone to change by the dryness. So, above two tests become important.

Check-point

- ① Moisture value in magnetic sheet

(content ratio of moisture) - ② Adhesive power

(power to peel the protective film off) - ③ Curling of the magnetic sheet

- ④ The noise when the protective film is peeled off

- ⑤ Degree of adhesion between the protective film and the sheet

- ⑥ Smell of the magnetic sheet

- ⑦ Adhesive power when the protective film is peeled off by hand

※ Above ② is checked by instrument and ⑦ is by hand

Test instrument

- ① Electric scales

- ② Tensile tester

Storage sample

Paper product is prone to change of the quality such as expansion and contraction by moisture and temperature in the place. For magnetic sheet, the expansion and contraction bring curve (wave), bubble and curl of the sheet and the protective film. For the claim about the quality from consumer, we usually do our best to answer them whether the quality problem was occurred by our production or consumer’s storage environment. We are sure to keep all magnetic sheets for 3 years in our factory since those productions and keep filing any data from the quality test.

As the result,

The magnetic sheet is not curled.

There are indicators to check the moisture value in our production line which enable us to do the production according to the moisture value of paper, temperature and moisture in the factory. The sheet is also made of compounded papers resistant to the moisture. The magnetic sheet is not curled due to the proper adjustment of the moisture-value.

High quality conserves your picture.

Nakabayashi’s photo album is produced under complete control at factory such as paper’s quality test, the magnetic sheet quality test and the sample storage to check the quality again when it is needed. The high storage stability can keep your precious pictures (memories) unchanged for a long time.

2. Quite new “original” products developed by Nakabayashi

Long lasting self-adhesive sheet

High durability self-adhesive sheet which the surface of the sheet has been coated by aluminum foil remains the quality unchanged for 100 year. The coating maintains a constant level of the moisture in the paper and prevents the paper from absorbing water in the air and drying. The light-resistance of the sheet also decreases the risk of the paper-burn by the light.

Another long lasting self-adhesive sheet (PET sheet)

The self-adhesive sheet coated by PET (polyethylene terephthalate) can protect it from ultraviolet which the light resistance is 5 times higher than that of non-coating sheet. With this, the risk of color-deterioration like yellowing can decrease very much. The quality is, even under high temperature and humidity for a long time, less prone to deformity or deterioration.

Prevent color deterioration of self-adhesive sheet and picture

Coating the self-adhesive sheets with aluminum foil or PET shuts the air out and protects the sheet from ultraviolet, heat, moisture, oxide such as ozone, exhaust gas bringing color deterioration or deformity of the sheet. Besides, the protective film covering the sheet also shut the air which may bring color deterioration of the picture printed by ink-jet printer.

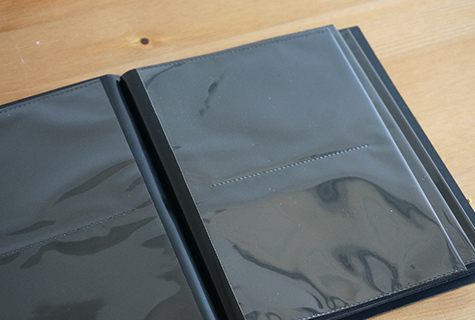

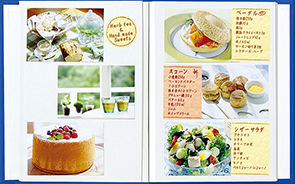

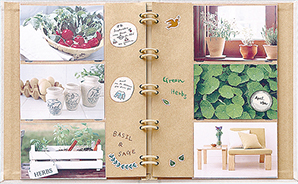

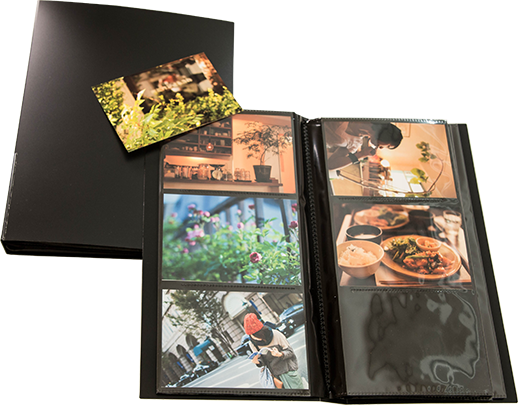

Our pocket album

The pocket sheet is less affected by moisture because the protective film is partially attaching to the sheet with glue instead of fully covering the sheet with the film like adhesive sheet. One of our ranges is the pocket album made of kraft paper which appeals the attractive design to consumer. These pocket albums are produced under our through quality control.

About the pocket sheet, partially glued to the PP (protective) film

The pocket sheet is made of paper and film. The paper expands and contracts by moisture but film does not do that, then, the pocket sheet finally curls and bubbles. But our pocket sheet is that the paper and film is partially attached with glue and most parts are separate, then, even if paper expands and contracts, the film is not affected by it. Therefore, it prevents the pocket sheet from curling and bubbling.

Crystal clear pocket sheet

Our crystal clear pocket sheet is made of crystal clear (OPP) film and black (CPP) film . Any pictures will stand out by this crystal clear film and black sheet.

Such a pocket sheet which OPP film and CPP film welded has never existed before our pocket album launched, then, it has been patent-pending.